Well screens

There are two types of wells: the « well recognized » and development wells. A « well recognized » or exploration well is drilled in a field that has never been explored before. A development well is drilled into an existing oilfield to extract more oil.Well screens

There are two types of wells: the « well recognized » and development wells. A « well recognized » or exploration well is drilled in a field that has never been explored before. A development well is drilled into an existing oilfield to extract more oil.

Both above wells can be drilled in various ways. They can be vertical, horizontal or multilateral. Vertical wells represent the traditional form of oil well drilling.

The horizontal and multilateral wells are increasing the length of the section in contact with the tank so they are more productive and also allow drilling in a reservoir where vertical access is difficult and also consolidate on the same surface, more wellheads.

The horizontal and multilateral wells are more expensive and it is important to select the drilling and completion equipment to optimize the cost by ensuring the success

The solid particles produced by a well may be constituted by fine particle formation or load bearing solid which move freely through the formation.

Euroslot Pars offers different technologies retentions solid particles to ensure optimal well completions.

- Slotted Liner

- Direct wire wrap

- Base Pipe Screen

- Prepacked Screen

- Premium Screen

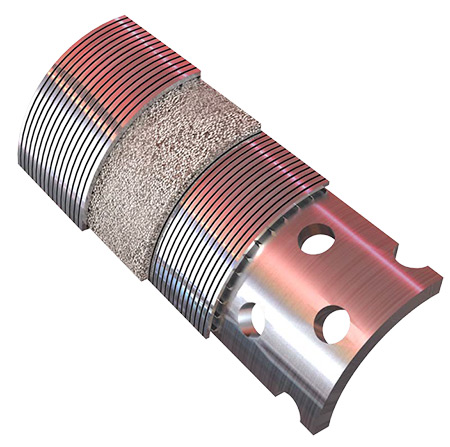

Direct wire wrap screen

Direct wire wrap screen is extremely resistant manufacturing method consisting of the wire and support directly wound on the perforated tube leaving the longitudinal ribs in intimate contact with the tube surface. In difficult horizontal wells during the friction of sand control systems installation damages the filtering surface and Direct wire wrap screen is best suited for use in extreme conditions thanks to the excellent mechanical properties.

Features

- Optical measurement of wire-wrapped gauge

- Uniform gauge for reliable sand control

- Intimate contact between supports & pipe

- Highest mechanical Resistance

- Superior installation loads

- High open flow area based on screen gauge

- Increased well bore longevity

- Low entrance velocity with lower friction forces

- Proven and advocated technology in horizontal app

Pipe Base Screen

Pipe Base Screen consists of a strainer fitted over a perforated tube, the outer screen is formed of V-shaped profile wire welded on the ribs to each intersection point. Slip on sand control is commonly used in vertical or horizontal wells due to its high mechanical strength.

Premium Screen

Features

- Customized design available

- Filtration supports available in different grades (304L, 316L or other specific Alloys)

- Specific wire wrap support and drainage base screen to ensure maximum flow velocity and protection of the sintered mesh

- Continuous spiral welded perforated shroud 316L will provide high mechanical resistance and protection to the sintered mesh filter, with large open area (35% minimum)

- Heavy duty construction for severe field conditions

- Optional Spiral Blade Stabilizer available on demand

Prepacked Screen

Features

- Customized design available according to client’s specs

- Base pipe according to API5CT with optimized perforation open area

- Dual layers of “V” Shape wedge wire filtration supports available in different grades (304L, 316L or other Corrosion Resistant Alloy)

- Optimized screen stand-off on base pipe to ensure high drainage and uniform circulation of fluids

- Wedge wire heavy duty construction with large number of rods to reach high tensile strength

- Very high sand retention efficiency

- Pre-pack available with free sand or resin coated gravel

- Optimized gravel pack thickness

- Optional Spiral Blade Stabilizer available on demand

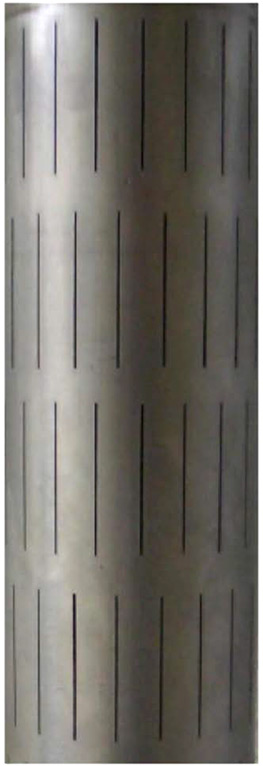

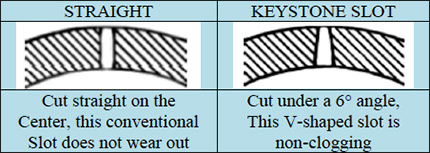

Slotted Liner

Slotted liner is a filter for retaining the solid particles in very severe conditions thanks to the excellent mechanical properties.

The slotted liner is a robust and cost-effective solution for long completions or low productivity wells.

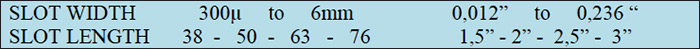

The slotted liner is manufactured with the fastest multi spindle slotting equipment in the world. The 40 ft-80 spindle milling machine produces slot in one pass over the entire length of the joint We can handle joints with length up to range 3 and diameter from 1.9” up to 9⅝

Upon request, we can cut any length of slot in any width

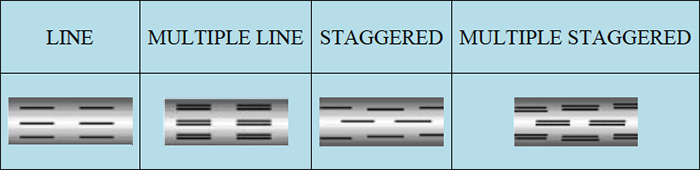

Both slot types can be cut in the line-pattern and the staggered-pattern. With the multiple patterns the open area can be increased by 4 times compared to single cut pattern.

Every joint slotted by Euroslot Pars is deburred internal and external and drift tested according to API standards. Every slot visually inspected and cleaned of burr material. All threads and couplings are thoroughly cleaned and lubricated.

The size, grade and weight of the base-pipe are according to A.P.I casing or tubing specification.

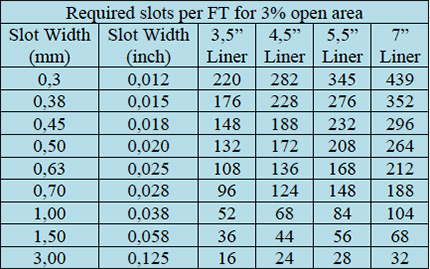

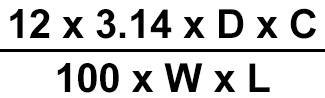

Number of slots calculation per foot

(N) NUMBER OF SLOTS PER FOOT

(D) OUTSIDE DIAMETER OF LINER (Inch)

(W) SELECTED SLOT WIDTH (Inch)

(L) LENGTH OF SLOT (Inch)

(C) OPEN AREA PERCENTAGE