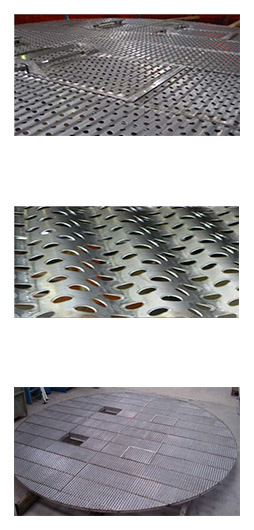

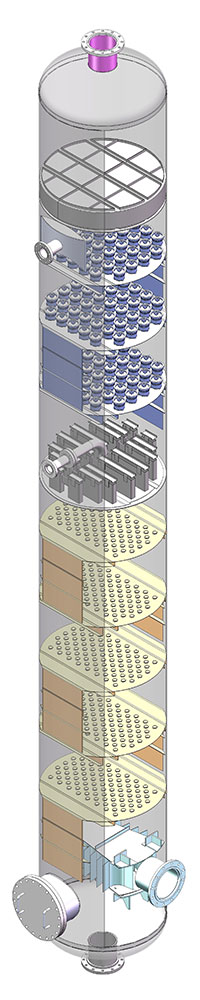

Dual Flow Trays

Dual flow trays are sieve trays that do not have downcomers. The term dual flow comes from the countercurrent flow of the vapor and liquid through the perforations. Thus vapor rate maintains the plate liquid level and the hole size will be defined for optimizing the performance.

Dual Flow Trays

Dual flow trays are sieve trays that do not have downcomers. The term dual flow comes from the countercurrent flow of the vapor and liquid through the perforations. Thus vapor rate maintains the plate liquid level and the hole size will be defined for optimizing the performance. High open area dual flow trays have a higher capacity and lower pressure drop than comparable to conventional trays. Dual flow trays is best solution that suit systems containing a moderate to high solids content Ripple trays is an dual flow trays forming the waving sheet which have the greater capacities and reduce the fouling without disturbing the vapor- liquid distribution.