Separator internals

Mechanisms removable droplets The droplets are extracted from a vapor stream through series actions: collision and adhesion to target coalesce into larger droplets and drainage of the contacting element.Liquid / Gas and Liquid / Liquid Separator

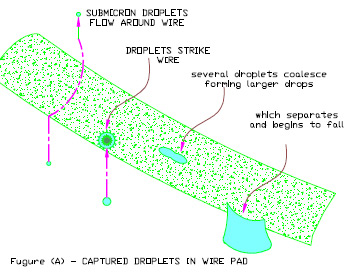

Mechanisms removable droplets The droplets are extracted from a vapor stream through series actions: collision and adhesion to target coalesce into larger droplets and drainage of the contacting element. The sizes of the droplets is an important element because the empirical data show that the important target size in the first removal step should be in the order of magnitude as the particles to be removed. These steps are shown schematically in Figure (A) for the Elimination of fog with metal mesh mist elimination.

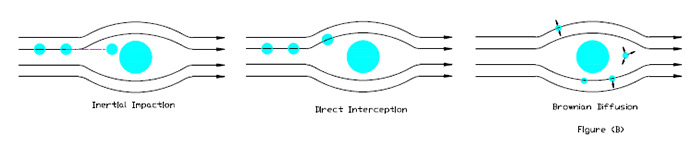

For mists, wherein the majority of droplets are characterized by submicron diameters, the energy required to cause the collision with the target is derived from Brownian diffusion, the aleatory movement of fine liquid particles as they are pushed by action molecular as shown “inertial Impaction”. This includes removal of mists with the so-called fiber bed technology

For particles in the spray area between 4-20 microns, wire mesh is the most common type of mist eliminator used and interception is the main mechanism. Consider a droplet approaches a filament of a much larger diameter mesh « Direct interception ».

More the droplet is dense relative to the filament, and the gas velocity is elevated more likely it is that the droplets strike the filament.

If the velocity is too low, or droplets are small or too light compared with gas, the droplet will simply flow around the filament with the gas.

There are also particles in the gas stream that are smaller between 0.3 to 1 micron in diameter and these do not have sufficient momentum to break through the gas streamlines. Instead, they are carried around the target by the gas stream.

If the velocity is too high, liquid hooked to the filament will be re-trained, mainly in large droplet, and carried away by the gas. Re-entrainment is also favored by the low density of the liquid and low surface tension of the liquid

Even small particles, generally smaller than 0.3 microns in diameter, exhibit a random Brownian motion caused by collisions with gas molecules. This aleatory movement will cause these small particles to hit the target and be collected, even if the gas velocity is zero. The particles diffuse from the streamlines to the target surface when the concentration is zero. Diffusion is favored by low velocity and high concentration gradients.

Even small particles, generally smaller than 0.3 microns in diameter, exhibit a random Brownian motion caused by collisions with gas molecules. This aleatory movement will cause these small particles to hit the target and be collected, even if the gas velocity is zero. The particles diffuse from the streamlines to the target surface when the concentration is zero. Diffusion is favored by low velocity and high concentration gradients.

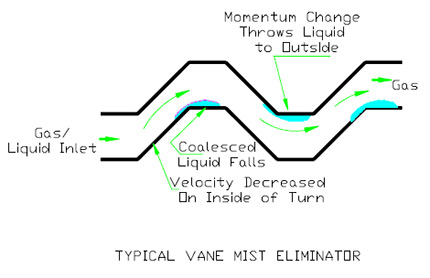

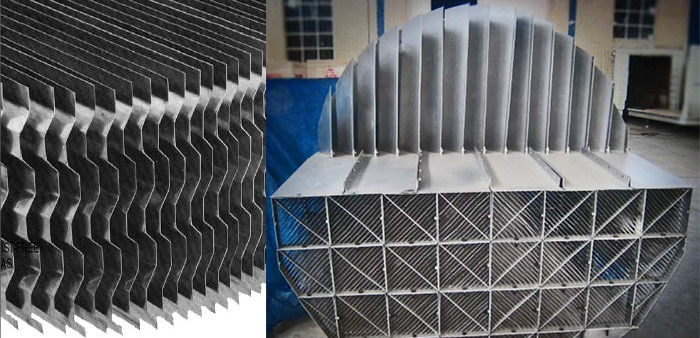

Baffles type of impingement mist extractor consists of a series of Vane or plates between which the gas must flow. As the gas stream circulates through the plates, the droplets strike the surface of the plate, coalesce, fall, and are routed to the liquid collecting section of vessel. The most common is Vane or Chevron -Shape.

Liquid/Liquid Separation

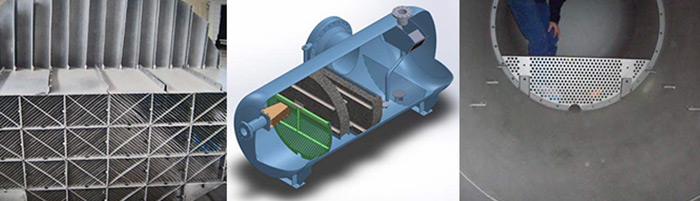

For liquid / liquid separations, we offer flat special pack in a wide range of materials. Depending on the requirement they may be used alone or in combination for separating a wide variety of emulsions mechanically induced. All separating packs are built to customer specifications or performance and high efficiency requirements and long reliable service.

HP-Coalescer

This type of coalescer consists of a combination of inclined parallel plates with fixed spacing determined according to the application and the degree of separation, so that the distance settling droplets is significantly reduced, which improves the process of coalescence. The inclination of the plates allows liquid phases to disengage diagonally towards liquid interface. The separation performance is improved by maintaining flow in the laminar region. The angle of inclination is between 45 to 60 °, with a plate spacing of 10 to 100 mm.

HV-Coalescer

Euroslot Pars coalescence produced from combination of two metal and plastic materials with different surface free energy to improve the two-phase droplet coalescence. This is an effective method that can be installed in vertical or horizontal position and the fastening system will be adapted to customer need. A wide variety of materials are available to meet different applications.

Liquid gas separation

Mist Eliminator

The conventional knitted mesh pads correctly designated give the good result in horizontal & vertical mist eliminator applications. But, the high gas velocity prevents the drainage of the liquid captured correctly. A thin liquid layer forms at the bottom part of pads at moderate gas velocity and liquid loads.

If the velocity or liquid loads increases again, the liquid zone becomes thicker, thereby causing total flooding of the pads. The liquid will be re-entrained and large droplets returned to the pads.

To solve the above problem, HMDS supply H-Opti-MESH®, this unique design is to create throughout reinforcements preferential capture zone liquid, this area sucks surrounding liquid drainage areas and surface tension allows fluid stream below this area thus allowing the gas to flow easily and increasing the ability of pads and reducing the pressure drop (Pressure drop)

H-Opti-Mesh can handle 20 to 30% more flow than a conventional mesh pads in the same service, Lower pressure drop compared to conventional mesh pads and High efficiency for capturing fine droplets.

Candle Mist Eliminator

Our mist eliminators candles are specially designed to be used in many processes generating mists, Its simple and economical design combines to its special texture in fiber allows it to be a flagship product and very effective in removing submicron liquid particles of gas and air streams. The fine particles of 0.1 to 3 microns are captured at 99% thanks to a texture fibers or fiber/metal mesh layer mounted between two concentric cages securely assembled. Fiber is precision wound to ensure optimum efficiency and pressure drop. Our candles are cylindrical but geometrically can be adapted to customer needs.

Vane Mist Eliminators

This type of impingement mist extractor consists of a series of vane or plate between which the gas must flow. The vanes force the gas flow to be laminar between parallel plates that contain directional changes. The surface of the plates serves as a target for droplet impingement and collection.

Chevron Mist Eliminators

Chevron packs are vane-type separators of high velocity droplets, when they are properly designed they can be very effective to collect droplets <10 microns in diameter. In general, they are used for the collection of droplets greater than 20 microns. Chevron is a solution as in the case of contains solid fluid with a special design that allows gas to pass vertically or horizontally between the blades. The variation of spaces between the blades allows high volume production capacity with low pressure drop We offer different type of Chevron that will specifically designed according to customer need.

Vane Inlet Distributor (VID)

VID devices are used in the phase separator in various applications principally for uniform distribution of the inlet flow through cross sections of the equipment. A uniform distribution of fluid across the cross-sectional geometries becomes important to minimize the drainage of fluid, which can result in reduced efficiency of the equipment.