Trayed column

Tray columns are used for making contact between a gas phase and a liquid phase so as to bring them as close as possible to the equilibrium state.

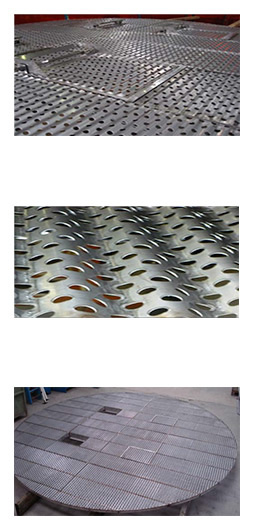

One of the most prominent hardwareis used for mass transfer is tray. Tray columns are widely used in various types of mass transfer operations. All the simulation results, which predict a certain number of theoretical stages, can be converted to actual trays depending upon tray efficiency for a particular service.

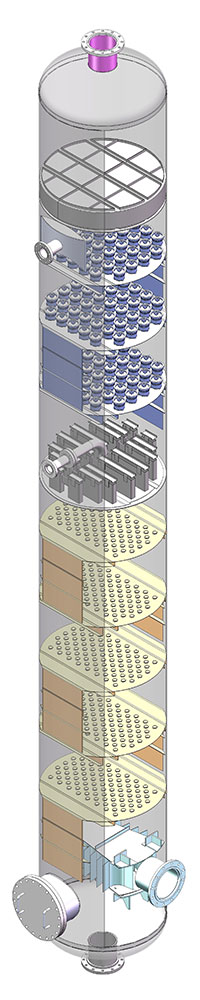

In any conventional tray vapor rises through the liquid pool on the tray deck and then disengages from the liquid in the space above the deck. Liquid enters the tray from a downcomer above and leaves via a downcomer below. Tray columns are used with equal success in distillation and absorption.

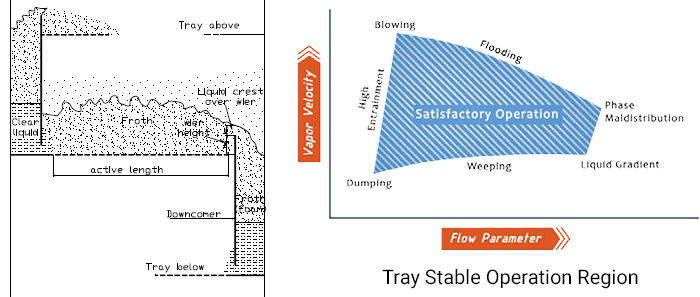

Minimum allowable capacity of a column is determined by the necessity of dispersion and contacting effective phases. The types of trays differ in their ability to provide low gas and liquid flow rates.

A sieve crossflow tray can operate at reduced gas flow to a point where the liquid is drained through the perforations and dispersion gas is insufficient for a good efficiency.

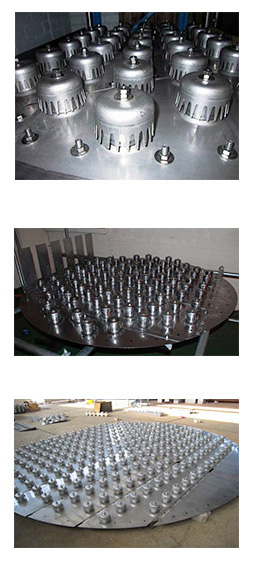

Valve tray can be operated at very low levels of gas due to the closing of the valve. Bubble cap tray can be operated at very low levels of gas due to their sealing arrangement.

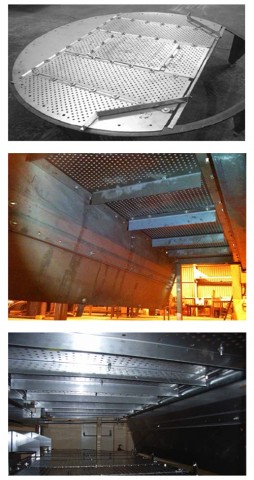

The Euroslot Pars valve trays combine high capacity and excellent efficiency with a wide operating range. HMDS have the knowledge and experience to assist you in optimizing performance for your application.

We offer a large range of column internals to various units of distillations & absorptions.

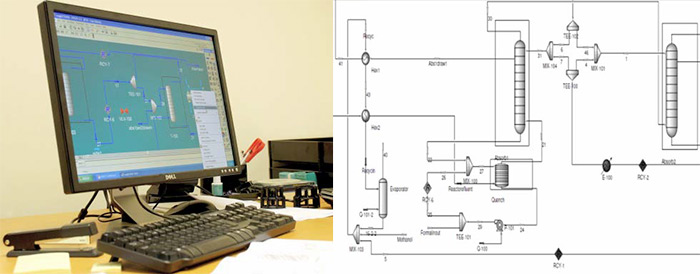

Process and Engineering Design.

Design of column internals is the essential element during which must be considered the requirements and specifications recommended by the Licensor by ensuring that the most advantageous configuration for the column internals was envisaged and implemented to ensure optimum design in point of view performance and internal installation.

- Process

- Hydraulic

- Mechanical

- Manufacturing

- Troubleshooting

- Debottlenecking studies

- Assistance in new developments

We propose the wide range of trays that its bubbling area can be customized using a variety of valve types depending on the application or service.

Design and technical services

- Compliance with international standard code

- Mechanical Calculation

- Hydraulic Calculation with performance guarantee

- Modelling software for pressure vessel

- Full AutoCAD drafting service

- 3D Drawing provided for all products

- Experienced staff in the design of products for the oil & gas and industries sectors

- We put our expertise and know-how in customer service

- We offer exceptional expertise in design and installation of catalytic reactors internals and distillation columns internals

- We study with the customer the most economical and performance solution.

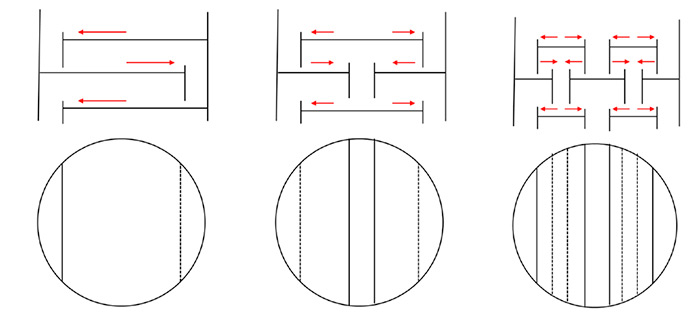

Depending on feed rates and column diameter, the number of passes can vary from 1 to 4.

.jpg)